Lotion Pumps for Skincare & Cosmetics: Top Chinese Manufacturer with Custom Lock Designs

Professional Lotion Pump Products China Manfaturer

Stdpak mold team expert keeps your Lotion pump up-to-date, meets SGS, ISO and Reach, etc.With 52 sets of Injection molding machines, 12 sets of dispenser pump making machines, automatic assembly machines.Stdpak has been serving customers from over 83 countries.

-

Cosmetic Bottle 24/410 Lotion Pump: High-Quality Dispensing Solution 2025

阅读更多 -

Grade Durable Lotion Pump Head with 10,000+ Cycles Long-Lasting Performance – Fits 24/410, 28/410 Bottles

阅读更多 -

Leak-Proof Lotion Pump Dispenser with Secure Lock – Mess-Free Travel, Adjustable Dosage, 24mm Fit

阅读更多 -

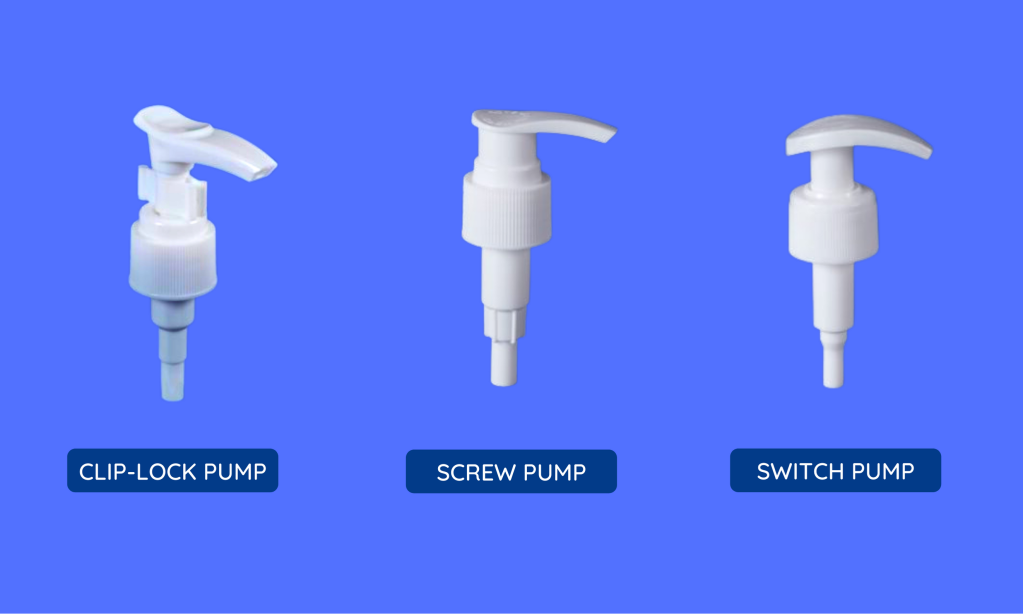

Lock – down mechanism lotion pump for secure transportation of liquid soaps

阅读更多 -

Recyclable pp lotion pump for eco – friendly personal care items

阅读更多 -

28/410 aluminum – collared lotion pump for luxury skincare products

阅读更多

Want To View Lotion Pump In More Styles?

QUALITY Lotion Pump MANUFACTURING

Send us your project’s needs, we will give you the best lotion pump solution based on your detailed requirement.

High quality lotion pump which use industry top material

All raw materials are from well-known brands and are environmentally friendly and meet FDA, SGS, MSDS requirements.

After assembly, Auto machines check again in the production line and filter out defective products by themselves. And finish dip tube assembly in time.

All accessories are completed in a dust-free workshop. At the same time, during the production process, we will carry out pressure tests and press tests to ensure that the product does not leak, block, or fall off.

STDPAK: Your Perfect Lotion Pump Manufacturer in China

If you are looking for Lotion Pump Manufacturers for your business, STDPAK will be your best choice to manufacture lotion pumps for your business.

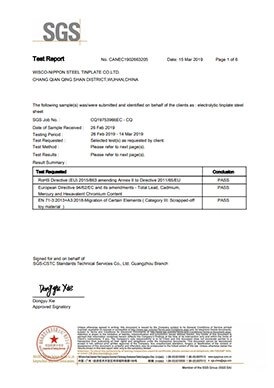

STDPAK is one of the leading lotion pump suppliers and all of our lotion pumps can meet and exceeds ISO14001, SGS, FDA, and REACH standards, and we will provide a competitive lotion pump price based on your project.

With over 16 years experience, our professional technical team know lotion pump mechanism well. If you are a plastic packaging brand and need to find an OEM lotion pump manufacturer, then STDPAK will 100% support to your lotion pump bottle.

STDPAK Lotion Pump

As a lotion pump manufacturer for over 16 years, STDPAK carries a huge range of different lotion pumps which are 20mm, 24mm, 28mm, 33mm, 38mm, 45mm fit and finish for your business and project. All types of lotion pumps have a high-performance design and built to withstand the harshest weather and environmental challenges.

STDPAK auto lotion pump assembly machine finishes the gasket, collar, and actuator on one line. 12sets of assembly machines can finish 10,000,000 Pieces/ Month.

Your Lotion Pump Experts

Over 16 years of lotion pump manufacturing experience, STDPAK’s daily production capacity of the pump is more than 300,000pcs, various nozzles are 200,000pcs, plastic bottles are 100,000pcs and the inventory will meet your urgent order needs.

A variety of process options can make your lotion pump more fashionable competitive. A flexible dispensing valve design allows for easy fitting of all types of plastic and glass bottles to your desired product category. The patent lotion pumps pending mechanism is designed to dispense as many products as it will to each dispensing slot. The dispensing valve has a locking mechanism to help prevent waste and maintain an ideal product selection. You can choose your pump lotions option to suit your exact preferences!

Competitive Price

With a wide and well-established supply relationship connected to the factory in China, Glamour offers Cosmetic packaging with exquisite at a low price.

Premium Quality

Strict Cosmetic packaging production quality control plans to translate into humanized designs, and material certifications.

Customized Service

From Material and color to pattern designs, you can have all the possibilities with a Cosmetic packaging Company.

On-time Delivery

With a mature production management system and a wide range of transportation methods, we deliver your products globally on time.

Helium Detection

Helium Detection

Quality Management System

Quality Management System

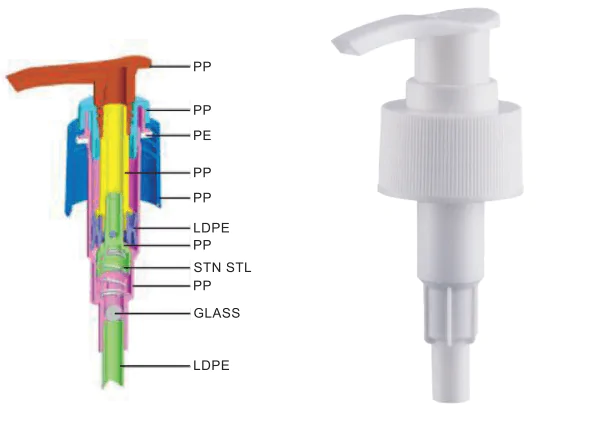

Lotion Pump Drawings

As a lotion pump manufacturer for over 16 years, STDPAK carries a huge range of different lotion pumps which are 20mm, 24mm, 28mm, 33mm, 38mm, 45mm fit and finish for your business and project. All types of lotion pumps have a high-performance design and built to withstand the harshest weather and environmental challenges.

STDPAK auto lotion pump assembly machine finishes the gasket, collar, and actuator on one line. 12sets of assembly machines can finish 10,000,000 Pieces/ Month.

Lotion Pumps: The Extensive FAQ Guide

1. What are lotion pumps mainly used for?

Lotion pumps are essential for dispensing various liquid products. They are commonly used in personal care items such as shower gels, body washes, creams, tonics, and massage oils. In the household, they are used for liquid soaps and detergents. Hair care products like shampoos, conditioners, and serums also often come with lotion pumps. Additionally, they are utilized for pharmaceutical products such as sanitizers.

2. What materials are lotion pumps typically made of?

Most quality lotion pumps, like those we offer at STDPAK, are primarily made from lightweight and durable polypropylene (PP). This material is chosen for its resistance to chemicals commonly found in the liquids it dispenses, ensuring a long lifespan and reliable performance.

3. How do I choose the right thread size for my lotion pump?

We offer lotion pumps with a range of thread sizes including 20 mm, 24 mm, 28 mm, 32 mm, and 38 mm, along with 400 and 410 thread styles. To choose the right size, measure the opening of the bottle where the pump will be attached. The thread size of the pump must match the bottle’s neck finish precisely. If the sizes don’t match, the pump won’t fit properly, and there could be issues with leakage or ineffective dispensing.

4. What nozzle (actuator) designs are available?

We offer lotion pumps with a range of thread sizes including 20 mm, 24 mm, 28 mm, 32 mm, and 38 mm, along with 400 and 410 thread styles. To choose the right size, measure the opening of the bottle where the pump will be attached. The thread size of the pump must match the bottle’s neck finish precisely. If the sizes don’t match, the pump won’t fit properly, and there could be issues with leakage or ineffective dispensing.

5. Can I customize the lotion pump's appearance?

Yes, we offer several options for customizing the appearance of lotion pumps. Special processes and treatments like external spring design, frosted surfaces, UV plating, and nested aluminum over closures for gold or silver colors can give the pumps a sophisticated look. Moreover, we can customize the color to match your brand’s identity. We also offer customization for dip tube length, which is important for ensuring proper liquid intake based on the bottle’s size and shape.

6. What is the minimum order quantity (MOQ) for lotion pumps?

Our minimum order quantity varies depending on the specific type of lotion pump, customization requirements, and current production capacity. For standard, non – customized lotion pumps, the MOQ is usually [X] units. However, if you require customizations such as unique colors, special nozzle designs, or specific packaging, the MOQ may be higher. Please contact our sales team for detailed information on MOQ for your particular needs.

7. How long is the production lead time for lotion pumps?

Once we receive your order confirmation and all the necessary details (including any customization requirements), the production lead time for lotion pumps is typically [X] business days. This time may be extended if there are complex customization requests or if there are unforeseen circumstances in the production process. We will keep you updated throughout the production process and provide an estimated shipping date as soon as possible.

8. Do you provide samples of lotion pumps?

9. What quality control measures do you have in place for lotion pumps?

10. How do I install a lotion pump correctly?

11. Can lotion pumps be recycled?

12. What if I encounter issues with the lotion pump after purchase?

Lotion Pump Related Products

-

33mm Foam Pump Dispenser for Hand Soap – Rich, Creamy Lather, Anti-Clog, Gentle on Skin

阅读更多 -

Leak-Proof Lotion Pump Dispenser with Secure Lock – Mess-Free Travel, Adjustable Dosage, 24mm Fit

阅读更多 -

Lock – down mechanism lotion pump for secure transportation of liquid soaps

阅读更多 -

Stainless Steel Foam Pump 40mm Gold Pump Head Foam Soap Foam Pump Top Supplier In China

阅读更多

Certifications

Renewable Natural Plant Fiber Cutlery Safety Certified & Conformity Certificate(EU)

ISO9001

ISO22000

SGS 2019 - REACH - EN

SGS 2019 - ROHS - EN

Guarantee Manufacturing & Shipping Time

You Deserve The Best

The tinplate MinJia used or offered is all from the top manufacturers in China, e.g. BaoSteel, Wisco-Nippon, TonYi. And is qualified by SGS test.

Quality Manufacturing

Loading time: 2 days

Well palleted or premium paperboard carton packed as per customer requirement, with soft loading into container, broken or fragile pick out

Shipping time: 15-30 days

We provide full set of custom clearance documents before you receive the vessel goods notification, get your goods from custom fruitly

Our Happy Clients!

Custom Lotion Pump Manufacturer In China

- Lotion Pump With more than 10 year of experience

- One-stop Lotion Pump solution

- High-speed and high-accuracy production line

- Annual on-site after-sale technical support